In the current tissue paper production industry, as consumer demands become increasingly diverse, the packaging sizes of tissue paper products have also become rich and varied. From small - sized pocket tissues for daily use to large - sized boxed facial tissues for household use, tissue paper packages of different sizes flood the market. Against this backdrop, whether the automatic tissue paper cartoning machine can handle tissue paper packages of different sizes has become a focus of attention for many tissue paper manufacturers.

I. Technical Feasibility

A. Mechanical Structure Design

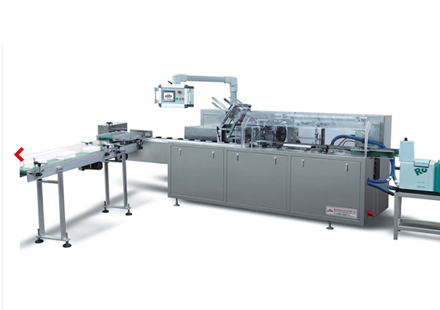

Modern automatic tissue paper cartoning machines take versatility into full consideration during the design process. Many devices adopt adjustable mechanical structures, such as movable conveyor tracks, grippers with adjustable spacing, and positioning devices. These designs enable the cartoning machine to flexibly change working parameters according to tissue paper packages of different sizes. For example, for tissue paper packages with different widths, the width of the conveyor track can be adjusted through motor - driven or manual adjustment devices to ensure that the tissue paper packages can stably enter the packaging boxes during the conveying process. For tissue paper packages with different heights, a liftable positioning platform is used to accurately position the tissue paper packages, ensuring their accurate position during cartoning.

B. Control System

An advanced control system is the key for an automatic tissue paper cartoning machine to adapt to tissue paper packages of different sizes. Most of the current cartoning machines are equipped with intelligent control systems. Operators only need to input corresponding size parameters on the control panel, and the control system can automatically adjust the actions of each execution component to achieve the processing of tissue paper packages of different sizes. For instance, sensors are used to detect the size information of tissue paper packages and feed the data back to the control system. The control system automatically adjusts parameters such as the action speed and gripping force of the cartoning machine according to the preset program to ensure the smooth progress of the cartoning process.

II. Market Demand - Driven

A. Meeting Diverse Consumer Demands

Consumers have different usage scenarios and demands for tissue paper, which has led to the emergence of various specifications of tissue paper products in the market. To meet the diverse demands of consumers, tissue paper manufacturers need to continuously introduce new packaging sizes. An automatic tissue paper cartoning machine that can handle tissue paper packages of different sizes enables enterprises to quickly respond to market changes, produce products that meet consumer demands, and enhance market competitiveness.

B. Reducing Production Costs

For tissue paper manufacturers, if a cartoning machine can only handle tissue paper packages of a single size, then when producing products of different sizes, multiple cartoning machines need to be purchased, which undoubtedly increases the equipment procurement costs and maintenance costs of enterprises. However, an automatic cartoning machine that can handle tissue paper packages of different sizes can meet a variety of production needs with one device, greatly reducing the production costs of enterprises and improving production efficiency.

III. Challenges and Solutions

A. High Precision Requirements

During the cartoning process of tissue paper packages of different sizes, the cartoning machine has extremely high precision requirements. If the positioning of the cartoning machine is inaccurate or the actions are imprecise, problems such as mismatches between tissue paper packages and packaging boxes and failed cartoning are likely to occur. To solve this problem, manufacturers need to continuously optimize the mechanical structure and control system of the cartoning machine, and adopt high - precision sensors and execution components to improve the accuracy and stability of the cartoning machine.

B. Long Specification Change Time

Although the automatic tissue paper cartoning machine can handle tissue paper packages of different sizes, when changing the packaging size, the equipment needs to be adjusted and set, which may take a certain amount of time. To shorten the time for changing specifications, manufacturers can develop quick - change die technology and one - click switching functions, enabling operators to complete the equipment adjustment in a short time and improve production efficiency.

In conclusion, the automatic tissue paper cartoning machine technically has the ability to handle tissue paper packages of different sizes, and market demand also promotes the development of this technology. Although there are still some challenges in practical applications, through continuous technological innovation and optimization, these problems can be effectively solved. Therefore, the automatic tissue paper cartoning machine can well adapt to tissue paper packages of different sizes, bringing higher production efficiency and economic benefits to tissue paper manufacturers.

GET A QUOTE